Serviced by Finbow

Spreader Roll Maintenance

Avoiding a single shutdown can save the cost of an entire spreader roll. Extend the service life of your spreader rolls with the best maintenance on the market.

Save time and money.

Finbow’s pre-emptive maintenance can give new life for your spreader rolls.

One-stop

shop.

Our service includes thorough testing and reports on your roll’s performance.

More running meters for your roll

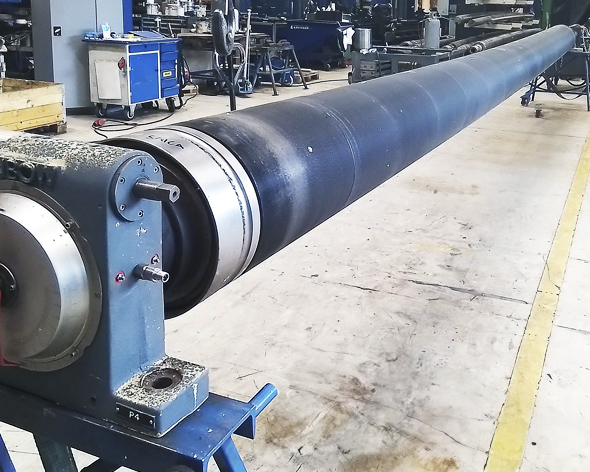

Functioning spreader rolls and precise control over the paper web help reduce broke, improve production quality, and prolong felt lifespan. Our spreader roll maintenance can give new life to any roll, whether made by Finbow or other manufacturers. Finbow’s patented solutions enable more running meters for the roll and can extend maintenance intervals by several years.

Addressing problems with your curved spreader rolls before they become actual defects and cause shutdowns can save valuable time and money. Investing in your current equipment is an important step in making paper and pulp production more sustainable.

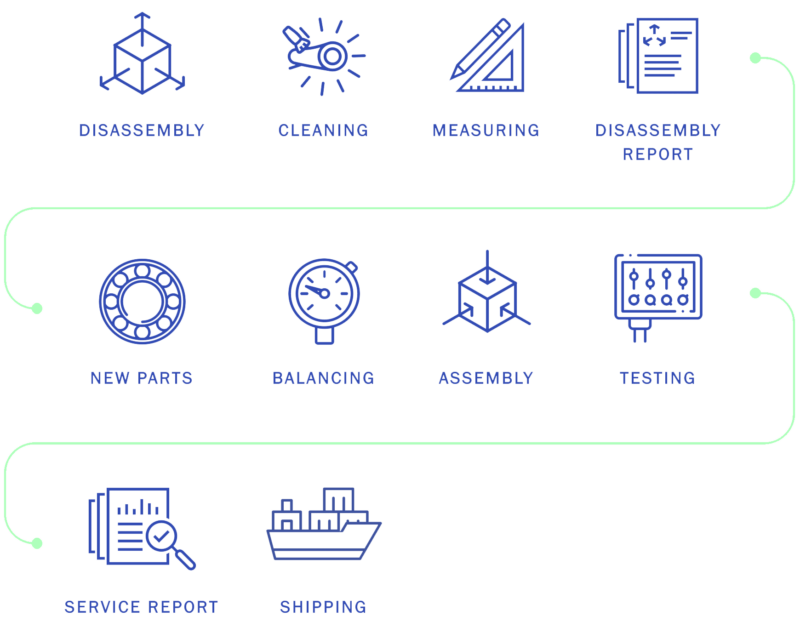

Service content

Our complete service model ensures that your spreader rolls come out good as new. We cover everything from disassembly, cleaning, and measuring to new parts, balancing, assembly, testing, and shipping – while providing comprehensive reports on disassembly and service.

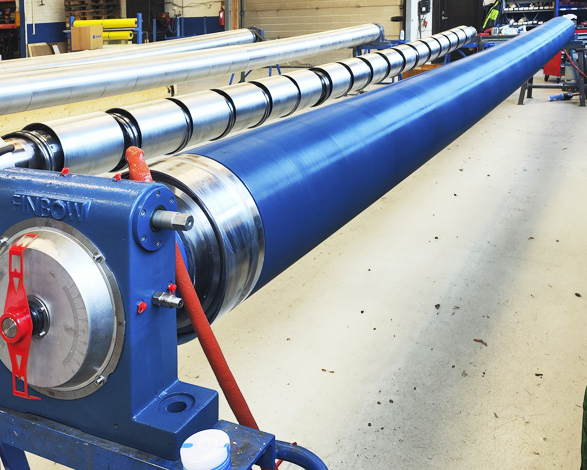

Proven quality and a 24/36-month guarantee

We pay careful attention to quality assurance, and take special care in considering the operating environments and features of your process when planning and performing maintenance.

The roll’s performance is always tested by simulating the actual drive environment as closely as possible. Our experts are always looking to find ways for improving the roll’s overall performance. As an assurance of our quality, a 24/36-month guarantee is offered for all serviced rolls.

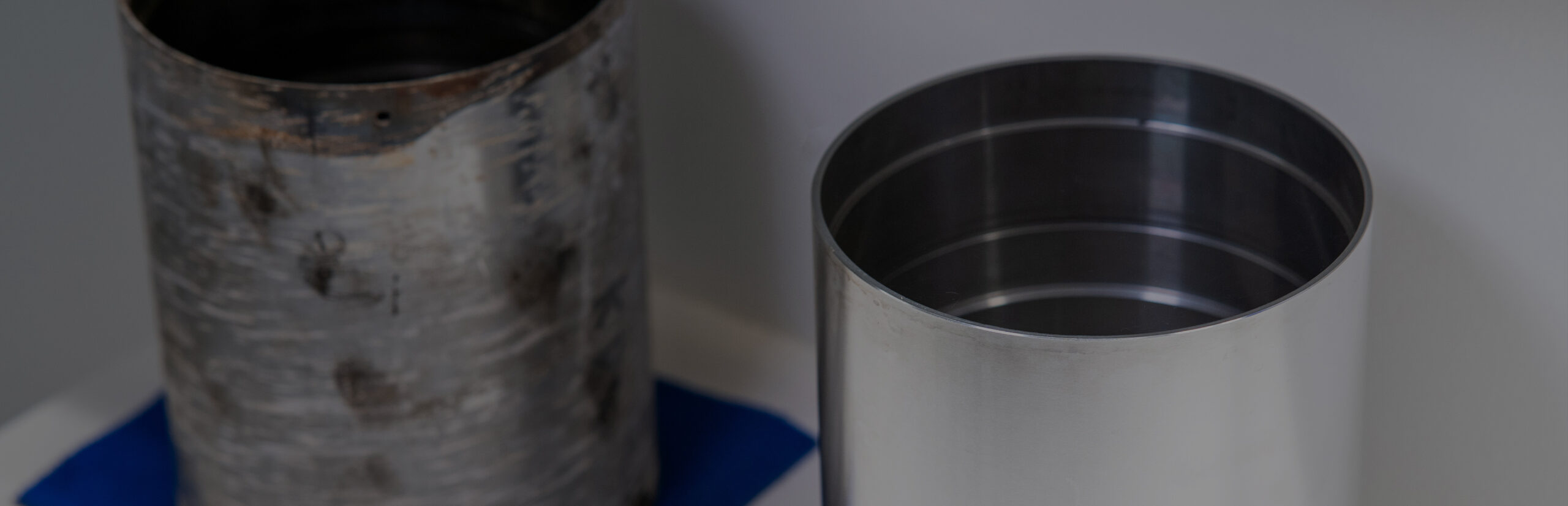

Roll before maintenance

Roll after maintenance

Even the smallest deformations in roll spools or bearing housings can cause malfunctions and unwanted vibrations when the spreader roll is moving at high speeds.

This is why we have invested in state-of-the-art 3D measuring equipment that can detect any anomaly and help us provide precision maintenance for spreader rolls by any manufacturer.