Smart solutions for any position

Built to Last

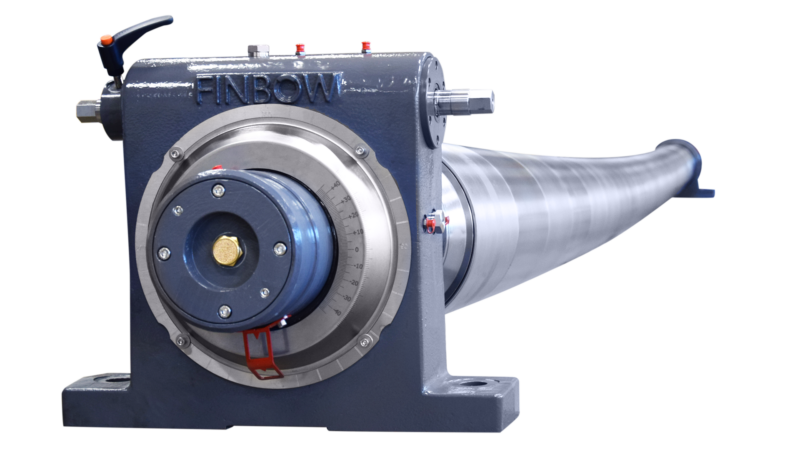

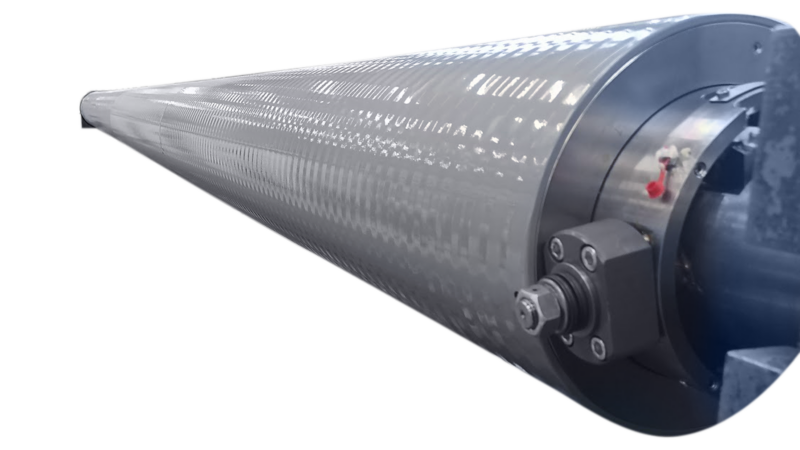

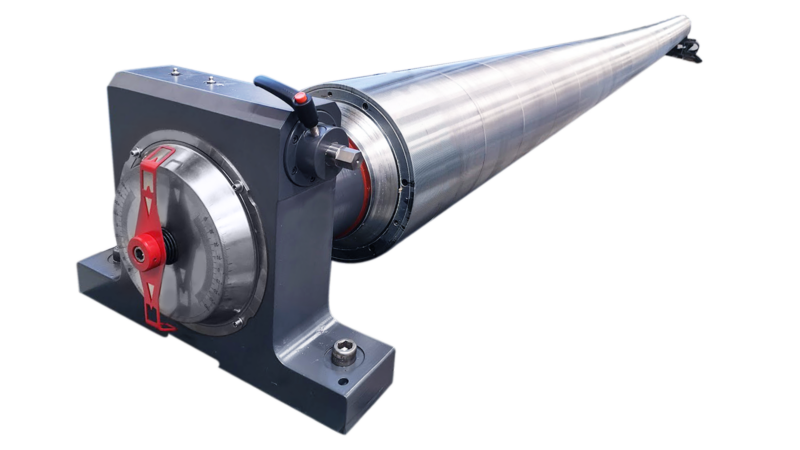

Each Finbow bowed spreader roll is designed and produced individually to match your production requirements. With a segmented design featuring steel spools, Finbow rolls prevent and eliminate wrinkles reliably even in the most demanding conditions.

Cover designs

| Machine position | Spool type | Coating | Coating | Coating | Surface design | ||

|---|---|---|---|---|---|---|---|

| HST | Carbon st | Chromium | NonStick T | NonStick N | MicroVenta | Plain | |

| Wire section | ++ | ++ | ++ | ||||

| Press section | ++ | ++ | ++ | ||||

| Sizer | ++ | ++ | ++ | ++ | + | ||

| Coater | ++ | ++ | ++ | ++ | + | ||

| Reel | ++ | ++ | ++ | + | |||

| Winder | ++ | ++ | ++ | + | |||

| Calender | ++ | ++ | ++ | + |

- Speeds < 1000 m/min generally plain roll

- WcT and WcNP vs teflon sleeve

- Coating on steel spool can last for many years

- 10 years is not unusual life

- Teflon sleeve expensive and easily damaged

NonStick T = Wolfram carbide Teflon

NonStick N = Wolfram carbide NanoPolymer

Frequently Asked Questions

The spreader roll (also known as an expander roll) is a roll that is most often assembled on a fixed, arched axle, the surface of which consists of steel segments. Finbow rolls have a rubber and metal coupler between the bushings that transmits power from one bushing to another, keeping the impurities and moisture safely outside the roll.

The efficiency of the spreader roll is based on the curvature of the roll, as well as the roll’s correct angle and speed relative to the path of the paper.

By adjusting the surface properties, the steel-coated rolls are suitable for all positions in a paper machine. A correct grooving on the surface gives characteristics to the rolls of a fast machine that cannot be achieved on a smooth surface.

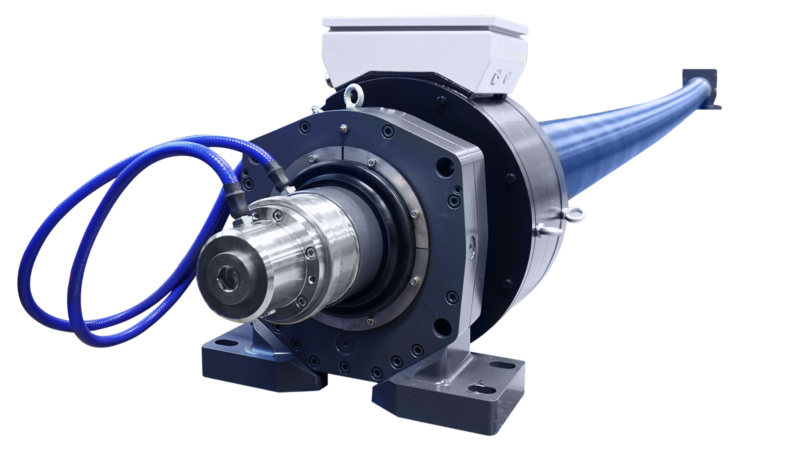

A fly roll is a roll designed to control the transverse tension of a super calender line. The purpose of the fly roll is to keep the paper path in a straight transverse direction, which keeps the paper’s quality constant.

The secret of the Finbow fly roll’s longevity lies in matching the roll’s properties (speed, temperature, moisture) to the operating conditions. Another important factor is the mechanical structure of the roll, which must be strong enough in relation to the diameter and length of the roll.

Finbow’s innovative rubber coupling transmits power from one bushing to another and keeps out impurities.