Set it and forget it! – This is why a fixed bow is the most reliable choice for spreader rolls

Finbow boasts nearly 40 years of experience in designing, manufacturing, and servicing bowed spreader rolls for various applications and positions in pulp and paper industry.

Over the years, we’ve consistently found that a fixed bow is far more reliable than a variable bow. Our servicing of variable bow rolls has shown that the tightness, sealing, and pressure of their hydraulic systems degrade over time. This degradation makes precise control over the curvature increasingly difficult.

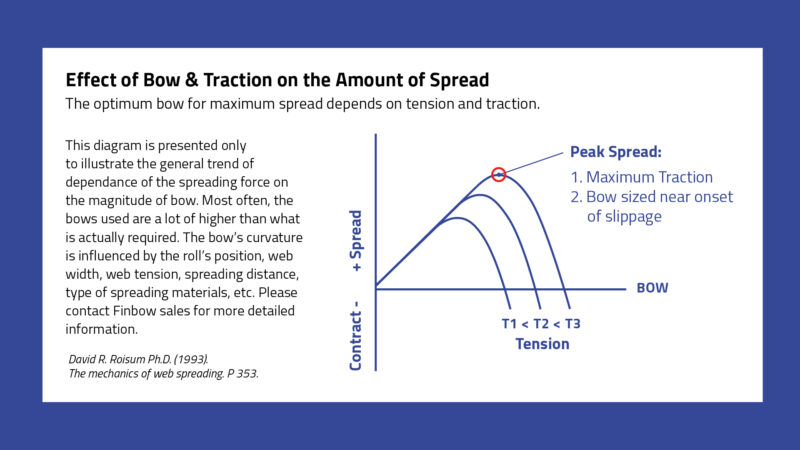

Moreover, it is easy to set the bow too high with a variable system. An excessively high bow reduces spreading, may even contract the web and spools near the roll’s edges to slip.

Our fixed bow spreader rolls are always designed to precisely match your production and operating environment. This means that they will always deliver optimal spreading and proven reliability.

| Fixed bow | Variable bow |

| Reliable: Consistent performance in all applications ensures effective web wrinkle removal. | Non-reliable due to hydraulic system losing pressure over time, more prone to slipping or web contracting if bow is set too high. |

| Cost-effective: Low manufacturing and maintenance costs, plus long service intervals. | Complex operation and maintenance, generally more expensive to manufacture. |

| Simple: Mechanically simpler and generally more robust due to fewer moving parts. | Often equipped with external controls for bow adjustment, require more complex and expensive maintenance. |

| Functional: Optimal and very precise bow magnitude is carefully selected during the design and manufacturing phase. No later adjustments are needed, ensuring consistent high-quality production with optimal spreading. | Challenges in operation and adjustment require skilled operators and deep knowledge on the required bow magnitude, significant chance of human error. |

Would you like to hear more about the benefits of a fixed bow roll? Don’t hesitate to contact our spreader roll experts!