Durability for demanding use

Spreader roll

coatings

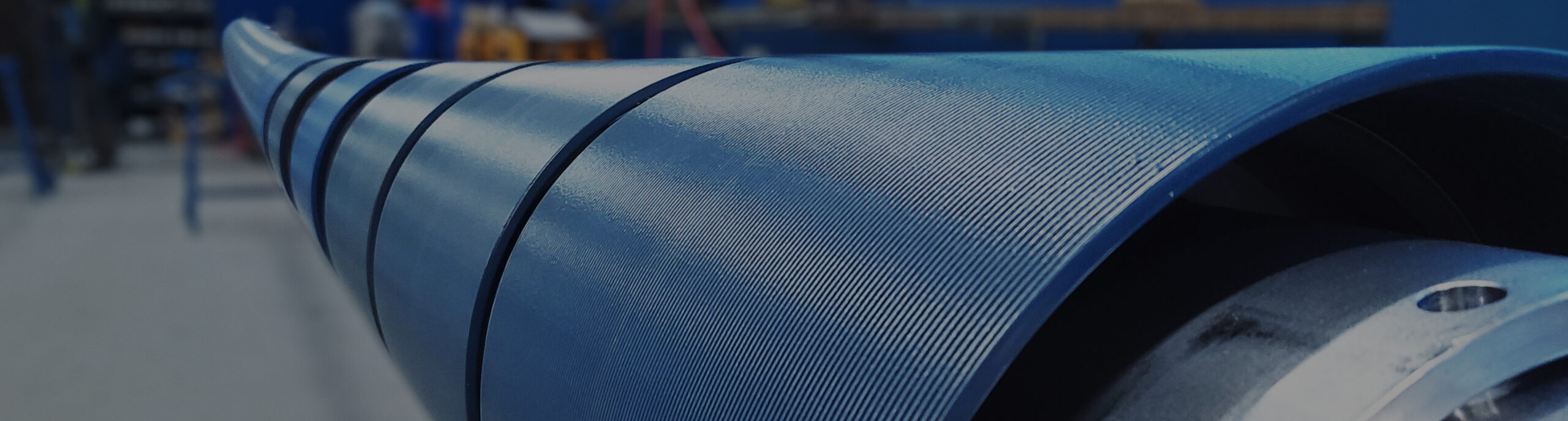

The Finbow NonStick T coating is specially designed for spreader rolls in abrasive conditions. The double-layer coating provides excellent wear resistance and premium non-stick properties.

Premium non-stick properties.

Our coatings help make spreader roll cleaning and maintenance easier.

Excellent wear resistance.

The Finbow NonStick T coating can extend the running life of your spreader roll.

Finbow NonStick T

Conventional spreader roll designs with plain chromium and rubber coatings attract stickies and grime. When longer running life, easy cleaning and increased drive times are required, we recommend our durable non-stick coating that guarantees maximum performance, premium rust resistance and easy cleaning. The NonStick T coating is recommended especially for spreader rolls in sizers and coaters.

Non-stick Finbow coatings can increase the uninterrupted drive time of a roll significantly when compared to rubber or chromium coated rolls.