Finbow – Genuine BowHow

Spreader rolls for the pulp & paper industry

Finbow is a leading expert in web spreading solutions. We design, manufacture, and upgrade advanced spreader rolls that meet all international quality standards and the needs of our global customers.

Spreader rolls

With over 3,000 delivered rolls, we know everything about the challenges of different operating environments.

Maintenance & Modernization

We help you improve your operational reliability with maintenance that increases roll service life.

Spreader rolls for every position

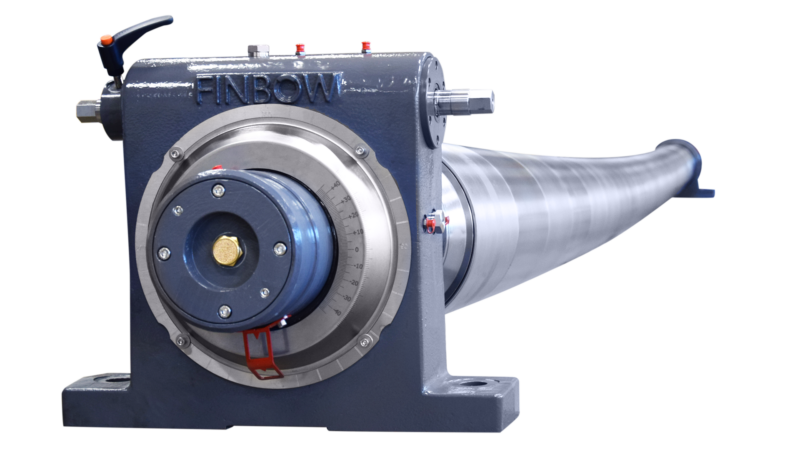

W Series

Felt and wire spreading in wet end applications

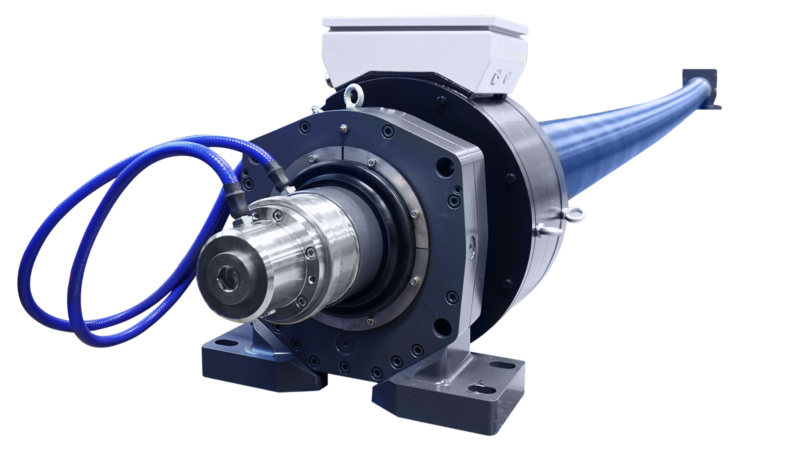

DN Series

Moist or dry applications with high temperatures and stickies

PDM Series

Felt and web spreading applications in pulp drying process

SC Fly roll / Take-out roll

For all supercalenders

SL Series

For slitter winder applications

Spreader Roll Maintenance & Modernization

Avoiding a single shutdown can save the cost of an entire spreader roll. Extend the service life of your spreader rolls with the best maintenance on the market.

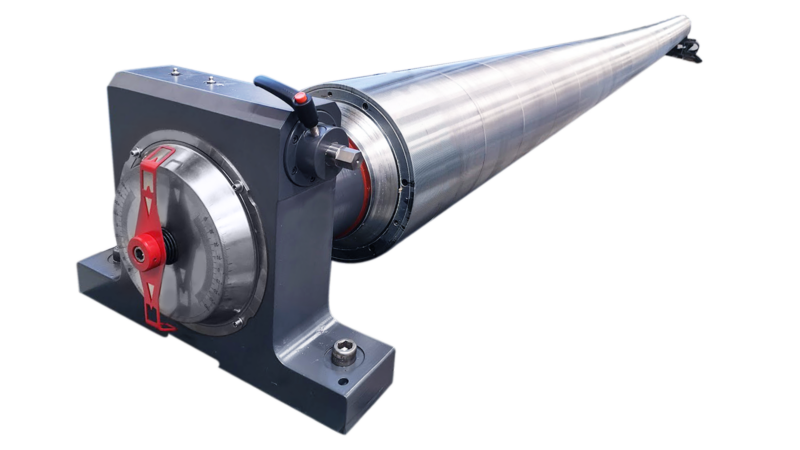

Functioning spreader rolls and precise control over the paper web help reduce broke, improve production quality, and prolong felt lifespan. Our spreader roll maintenance can give new life to any roll, whether made by Finbow or other manufacturers. Finbow’s patented solutions enable more running meters for the roll and can extend maintenance intervals by several years.

We cover everything from disassembly, cleaning, and measuring to new parts, balancing, assembly, testing, and shipping – while providing comprehensive reports on disassembly and service. As an assurance of our quality, a 24/36-month guarantee is offered for all serviced rolls.

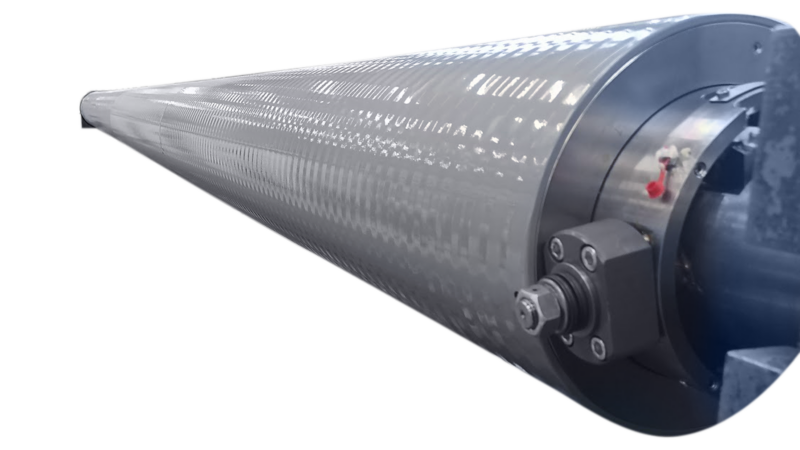

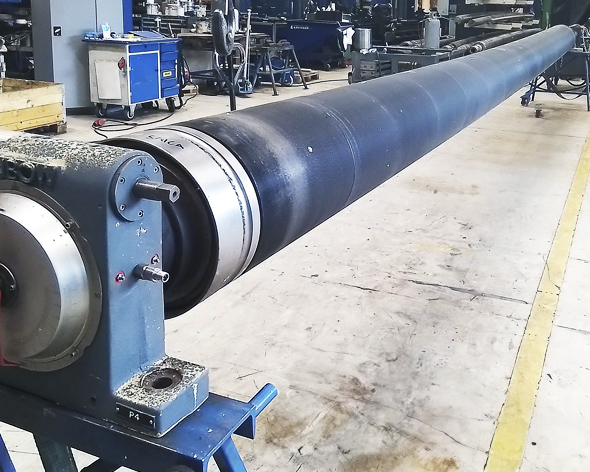

Roll before maintenance

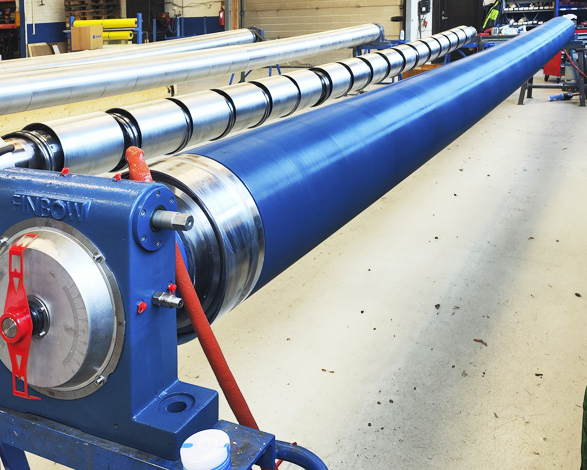

Roll after maintenance

Roll modernization

Converting your production line to produce another product doesn’t necessarily mean purchasing entirely new spreader rolls. Finbow’s own design department has plenty of experience in modernizing existing spreader rolls to match new specifications. Upgrading a rubber spreader roll sleeve to steel spools is a popular option for increasing the lifespan of your rolls.

Here are some of our solutions for spreader roll overhauls and refurbishments:

- Flexible couplings that prevent water and dirt from entering the roll, while allowing smooth rotation and low power consumption

- Reliable multi-phase end sealing systems against moisture and dirt that enable longer roll running times

- Finbow’s patented moisture removal system that improves operational reliability

- Modifiying a rubber roll with steel spools and a durable coating

- Direct drive functionalities with precise speed control

About Finbow

Finbow has been providing premium spreader rolls and service for the world’s largest and fastest pulp and paper machines since 1985. With over 3,000 bowed spreader rolls delivered to 45 countries worldwide, the Finnish company was originally founded to meet the service needs of Nordic pulp and paper factories.

Our global sales partners

Our rolls in operation

We have provided and serviced spreader rolls for the biggest and fastest paper, board and pulp drying machines in the world.

Main contact person:

Ms. Aslihan Yilmaz <

Main contact person:

Ms. Aslihan Yilmaz <